Hot-Dip Galvanizing Services

We depend on steel to provide a sturdy and long-lasting foundation for our buildings. But while solid steel is a strong and durable material, it is not indestructible. Rust can form on steel edifices over time, which can jeopardize their structural integrity.

Galvanization is a process that entails coating steel with zinc to prevent the onset of rust. Zinc is an extremely corrosion-resistant and relatively inexpensive metal that acts as a sacrificial barrier between rust and the steel substrate. The zinc coating will undergo oxidation and dissolve before the rust can reach the substrate’s surface. The dissolved zinc electrons flow to the portion of the steel that requires protection.

What Is Hot-Dip Galvanizing?

Hot-dip galvanization (HDG) is a variation of the standard galvanizing process that works well for protecting carbon steel. With hot-dip galvanization, the steel substrate is immersed in a vat containing molten zinc. The zinc reacts with the iron in the steel (carbon steel is comprised of approximately 90 percent iron) to form an alloy that provides excellent corrosion resistance.

Tracing the History of Hot-Dip Galvanization

The origin of the modern hot-dip galvanizing process dates back to the mid-18th century. In 1742, a French chemist named Paul Jacques Malouin developed a technique to coat iron by dipping it in molten zinc. In 1829, Michael Faraday discovered the sacrificial properties of a zinc coating through experimentation. Less than a decade later, a French engineer named Stanislaus Tranquille Modeste Sorel received a patent for the first known hot-dip galvanization process.

The first industrial galvanizing plant in the United States opened in 1870 and employed the process of hand-dipping steel into a zinc bath.

Today, hot-dip galvanization occurs in just about every manufacturing application involving the use of steel and iron. Each year, North American companies in industries such as automotive, pulp and paper, chemical and utilities consume approximately 600,000 tons of zinc for galvanization.

What Are the Benefits of Hot-Dip Galvanization?

There are many advantages derived from using hot-dip galvanizing to coat steel:

- Durability — Hot-dip galvanizing can provide long-lasting protection for steel structures and components. A galvanized coating can fend off corrosion for up to 50 years or longer.

- Toughness — A hot-dip galvanized coating is extremely thick and forms a tight metallurgical bond with the steel substrate. This minimizes the risk of damage from external forces.

- Low maintenance — A galvanized coating requires little or no preventive maintenance, which results in low service and upkeep costs over time.

- Thorough surface coating — Unlike some other commonly applied coating/finishing processes, hot-dip galvanizing can cover the entire surface of the substrate including crevices, edges, sharp corners and recessed area. This provides more uniform protection and maximum corrosion resistance.

- Fast application — The process of hot-dip galvanizing takes just a few hours to complete and the finished product is ready for immediate use/installation. This helps companies keep up with their tight manufacturing or production schedules.

- Affordability — Hot-dip galvanizing typically features lower upfront costs than many other popular steel coating techniques. When combined with the lower long-term maintenance expenses, the process provides an extremely cost-effective protective solution.

The Hot-Dip Galvanizing Process

The process of hot-dip galvanizing generally encompasses the following steps:

- Surface preparation — The failure to adequately prepare the surface of the steel substrate prior to immersion in the zinc bath can lead to insufficient coating adhesion or hinder the ability of the coating to cover the entire workpiece. Surface preparation is a multi-step process that includes:

- Degreasing — Degreasing the workpiece in a biological cleaning bath, hot alkali solution or mild acidic bath will remove grease, oil, dirt and other organic debris from the surface.

- Pickling — Pickling entails the application of a heated sulfuric acid solution to remove rust and mill scale from the surface.

- Fluxing — Fluxing involves the application of a zinc ammonium chloride solution to remove any remaining deposits and provide a protective layer to prevent oxidation prior to immersion.

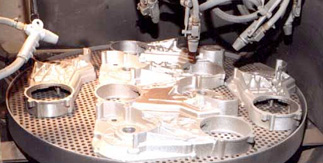

- Galvanizing — During galvanization, the workpiece is submerged in a bath consisting of 98 percent pure zinc at a temperature of approximately 840° F. Once the coating application is complete, the workpiece is removed from the zinc bath. Any excess zinc is removed via centrifuging, vibrating or draining. Cooling can occur by immersion in a passivation solution or exposing the workpiece to air.

- Inspection — The galvanized workpiece undergoes inspection and testing to ensure appropriate thickness and surface condition.

Contact Surtech to Learn More About the Benefits of Hot-Dip Galvanizing

Surtech Industries has perfected an innovative hot-dip galvanizing process that will fully protect your steel products from rust formation. Contact us to learn more today.

Contact Us!

- Address:

- 915 Borom Rd.

York, PA17404 - Phone:

- 717-767-6808

1-800-745-8176 - Online:

- Contact Us to request a free quote!

- Employee Directory:

- View our Employee Directory.

Definition:

Abrasive blast cleaning entails the forceful direction of abrasive particles against the surface of a product, to remove contaminants or to condition the surface for subsequent finishing. Present capabilities offer a wide range of manual and automated blasting processes to provide surface Ra finishes and cosmetic appearances up to a white metal designation (SSPC-SP10). Blast media include aluminum oxides, steel shot and grits, glass bead, and plastic media.